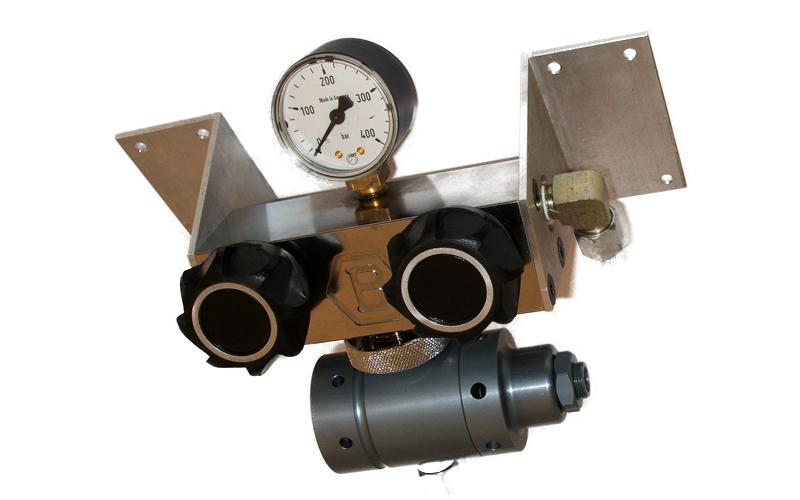

Orderly and compact design in which the components filling valve, pressure indicator and filling ramp merge into one part.

By using special valves , it has been possible to combine the essential requirements of a modern compressed air filling system in just a few components. These filling ramps can be operated with any breathing air compressor.

Here are the features in an overview

1. lever with self-venting: These lever valves can be supplied with red levers for 300 bar and black levers for 200 bar, making the different pressure ranges even more clearly visible.

2. flow reduction: this offers the advantage that composite compressed air cylinders can also be filled and excessive heat development is prevented, especially during the filling process via the accumulator. This means a better filling level of the diving cylinders and a quiet filling operation . If, however, the full flow version is preferred, where the focus is on rapid cylinder filling, the reducer can be converted in just a few steps.

3. check valve at the valve inlet ensures that only clean air from the high-pressure compressor enters the cylinder. This prevents backflow from other cylinders.

4. pressure indication at each connection : the pressure gauges are screwed directly into the filling valves, which considerably reduces the amount of piping required.

5. sintered filter: a sintered filter is fitted to each valve, protecting the valve seats from damage due to contamination. This means an extension of the maintenance intervals.

6. venting silencer for quiet filling operation: The newly developed extra silent venting silencers reduce the noise level during venting to a minimum. Especially when filling the compressed air cylinders via high-pressure filling hoses, the advantage of the silenced venting becomes clear.

7. safety filling tubes : For the versions with filling tubes, filling tubes are flow stop The filling tubes are placed in ergonomically designed holders.

8. RAL colours can be selected: as standard, our filling strips are finished with a special metallic coating, but any RAL colour can be used for the coating.

9. modular design : Brandner filling ramps are designed in modules, which allows a subsequent Second pressure range or a Automatic switch-on for accumulator can be mounted.

10. Low space requirement : If the filling point has limited space, 360° swivelling right-angled hose connections can be fitted to direct the hoses vertically downwards and thus save space.